Measuring What You Can’t See:

Why Corrosion Coupon Testing Is Essential

Corrosion Monitoring Matters

Corrosion is the silent destroyer of any water-based system. In cooling towers, closed loops, and boilers, it works gradually and often invisibly—until the costs become impossible to ignore. Field tests and visual inspections can show surface conditions, but they can’t quantify metal loss or pinpoint which alloys are truly at risk.

That’s where corrosion coupon testing makes the difference. It’s a simple, controlled, and data-driven way to measure what you can’t see happening inside your systems.

Precise corrosion coupon analysis turns weeks or months of system operation into clear, actionable corrosion rates. And because BLS backs every report with deep industrial water treatment experience, we don’t just provide numbers—we interpret what they mean and help you understand exactly how to act on them.

Inside a Corrosion Coupon

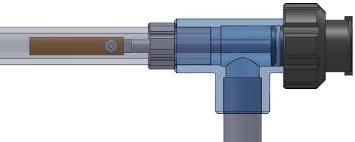

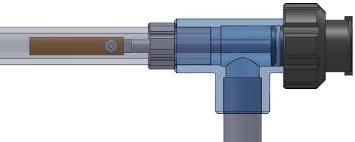

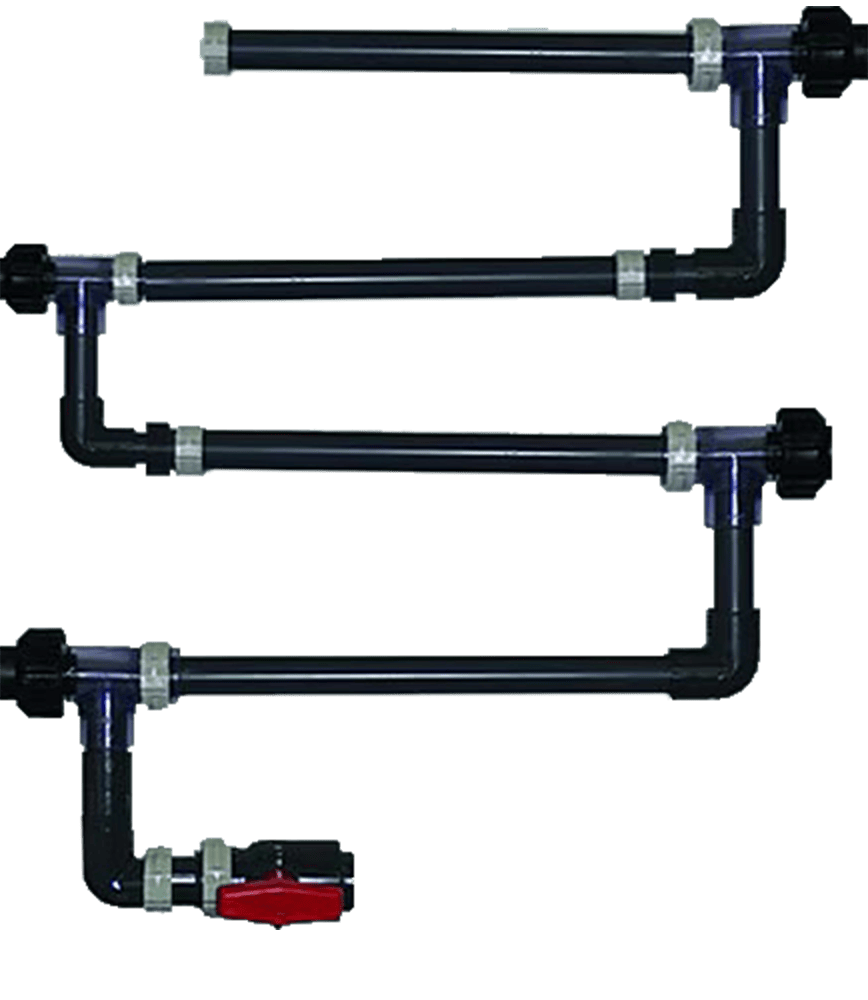

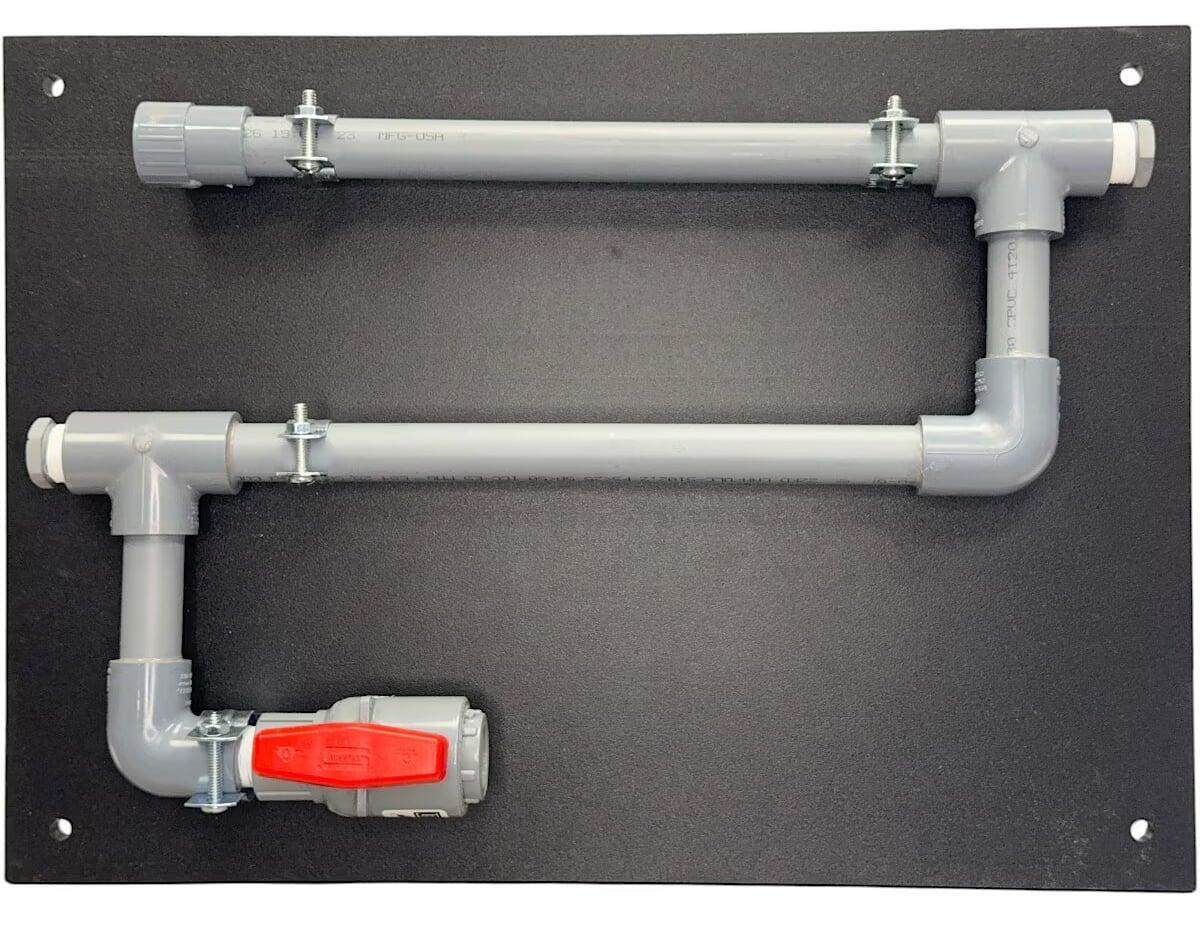

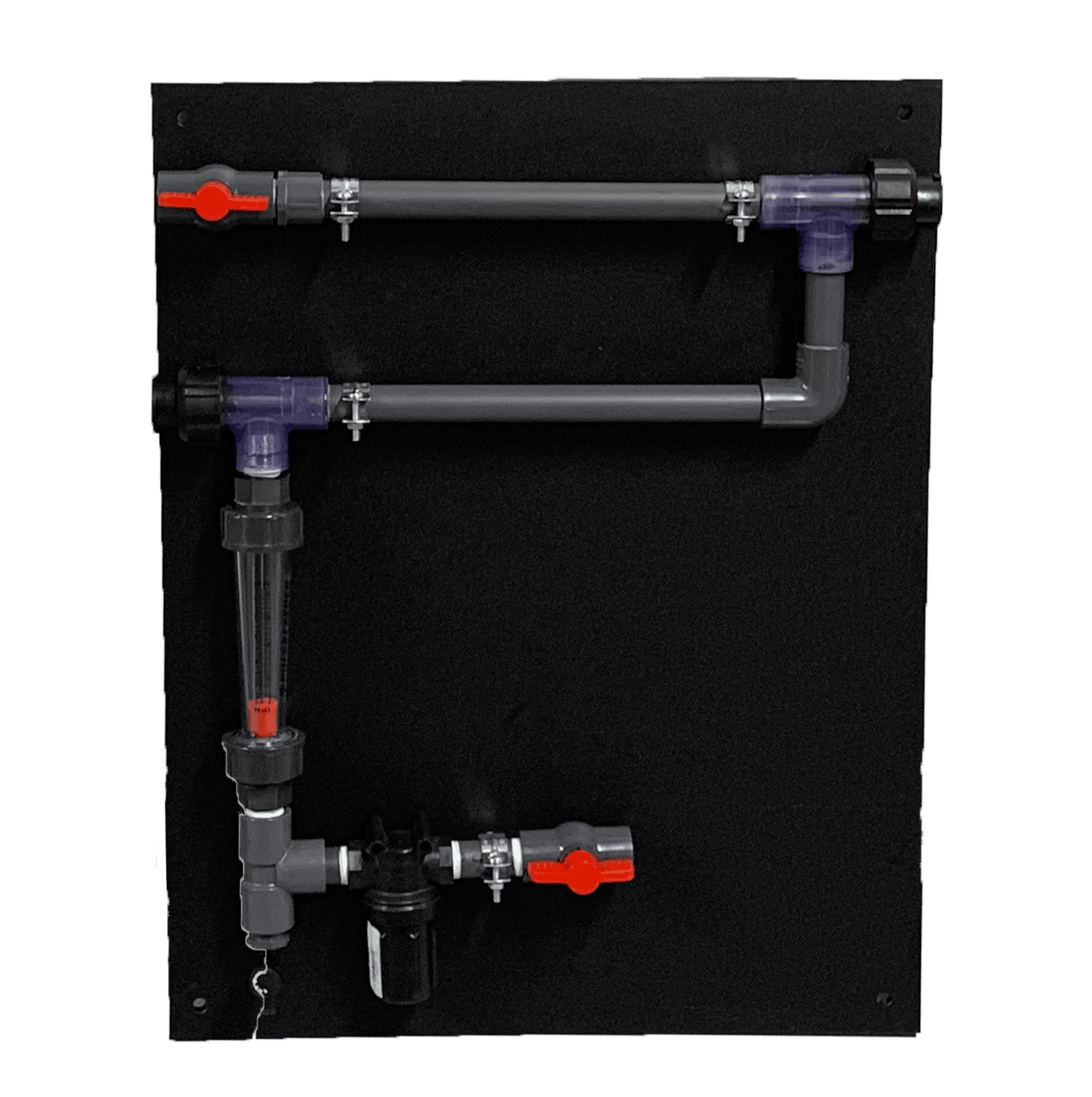

A corrosion coupon is a small metal strip—commonly mild steel, copper, or another alloy chosen to represent the system’s metallurgy—installed in the water stream and exposed to real operating conditions for a defined period (typically around 90 days).

Once the exposure period is complete, the coupon is retrieved, cleaned, weighed, and inspected for:

These findings provide operators with a clear picture of system health. By interpreting the results, teams can verify inhibitor performance, detect contamination, and monitor how operational or chemical changes are impacting corrosion over time.

Corrosion Coupons Materials and Standards

Corrosion coupon testing relies on consistent materials, standardized preparation, and controlled laboratory handling to ensure accurate corrosion rate calculations and meaningful surface evaluations. Most commercial laboratories—including Brothers Laboratory Services (BLS)—offer a range of coupon types suited to different system metals and monitoring objectives.

Commonly used coupon materials include:

- Mild Steel (BL-MS-COUPON)

- Copper (BL-CU-COUPON)

- Galvanized Steel (BL-GV-COUPON)

- Stainless Steel (BL-SS-COUPON)

- Admiralty Brass (BL-AB-COUPON)

- Aluminum (BL-AL-COUPON)

- BioMesh (BL-BM-COUPON)

Regardless of material, corrosion coupons should be processed under controlled conditions both before and after exposure. Standard laboratory steps typically include:

- Cleaning and preparation to establish a baseline weight

- Post-exposure cleaning following ASTM guidelines

- Accurate weighing for metal loss calculation

- Visual examination of pitting, deposits, and surface condition

- Documentation of corrosion rate (MPY) and physical observations

- Photographic records to support interpretation

These practices help ensure that the resulting data is consistent, repeatable, and comparable across systems and over time—whether you're validating a new treatment program, assessing inhibitor performance, or trending long-term corrosion behavior across multiple facilities.

BLS follows these industry-aligned methods to provide reliable, reproducible results, supporting water treaters who depend on accurate corrosion monitoring.

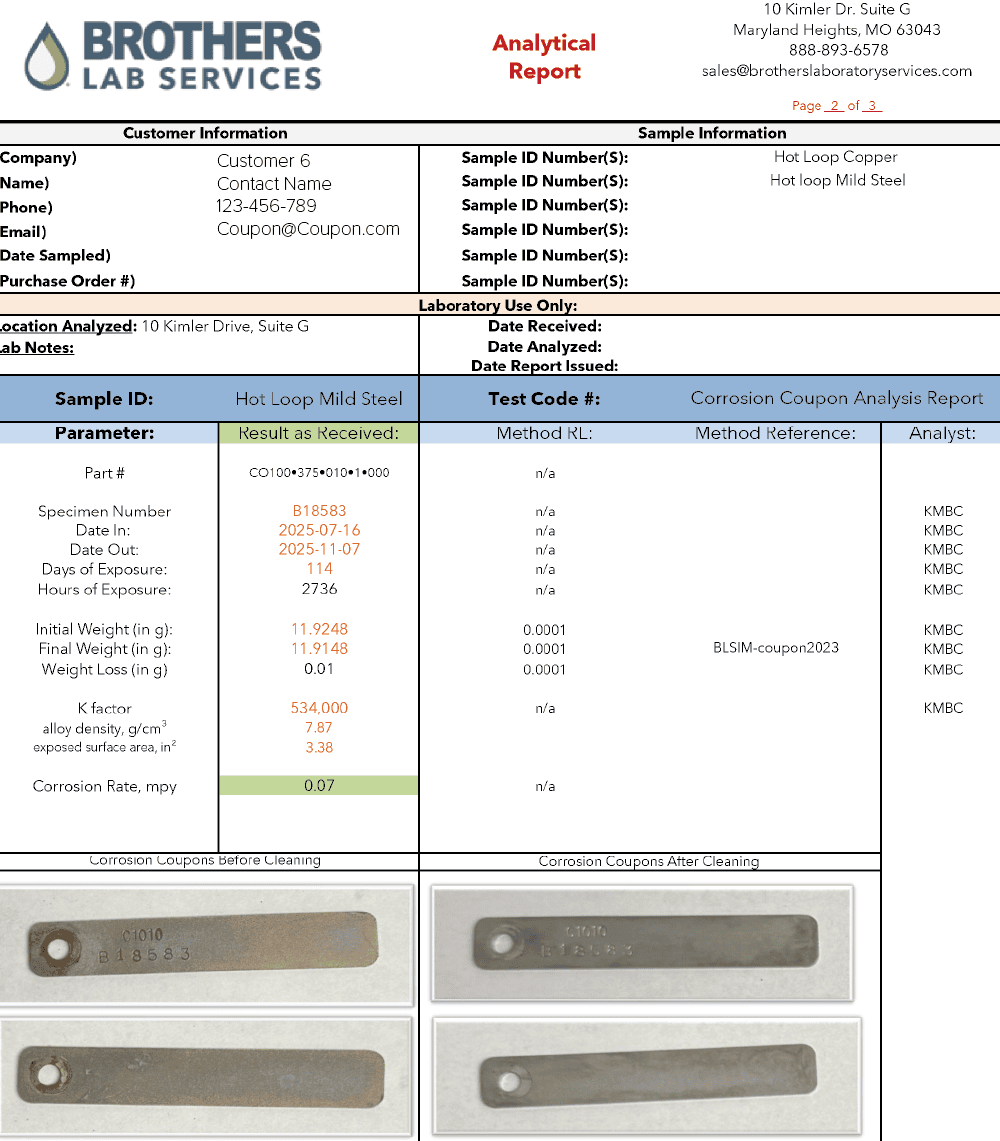

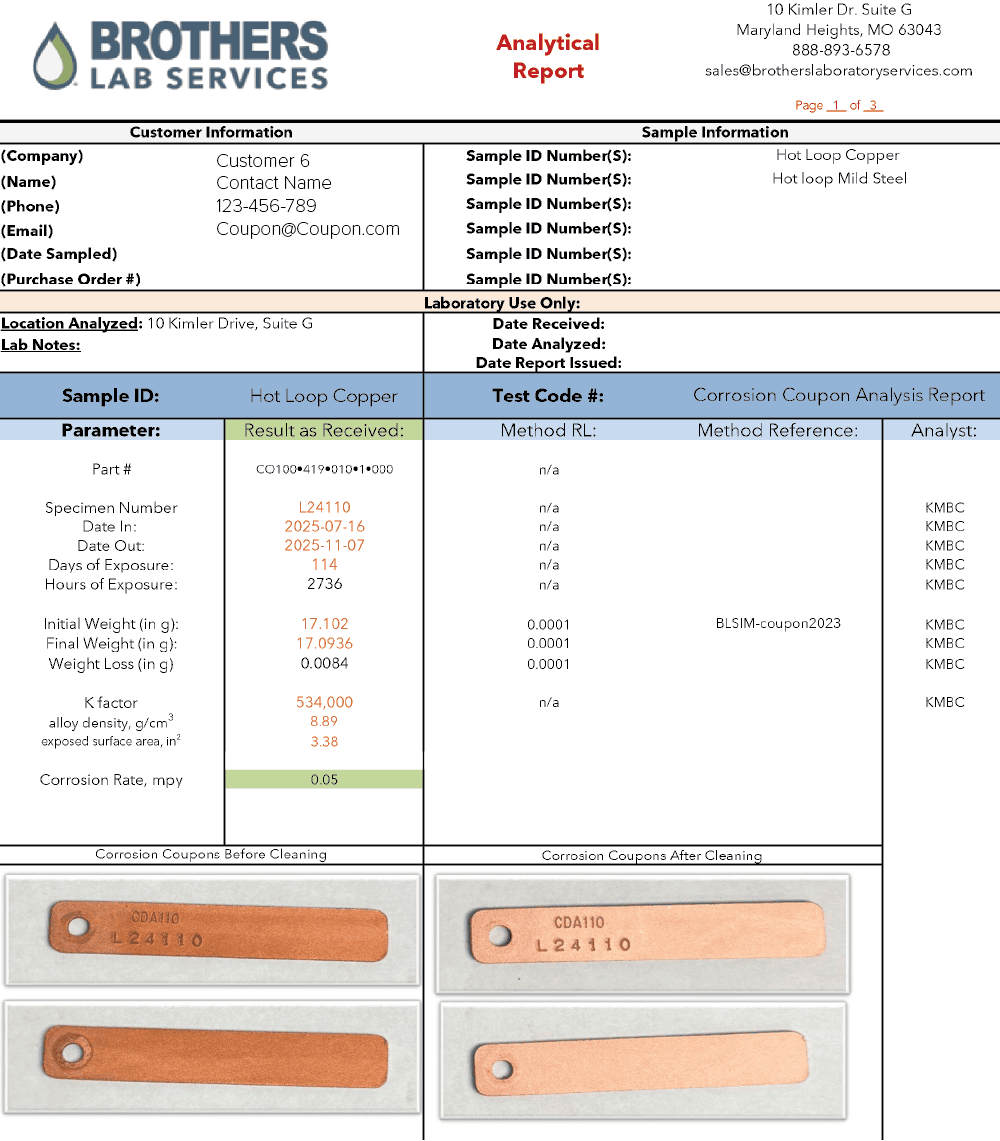

Corrosion Coupon Reporting

How to Interpret Corrosion Coupon Data

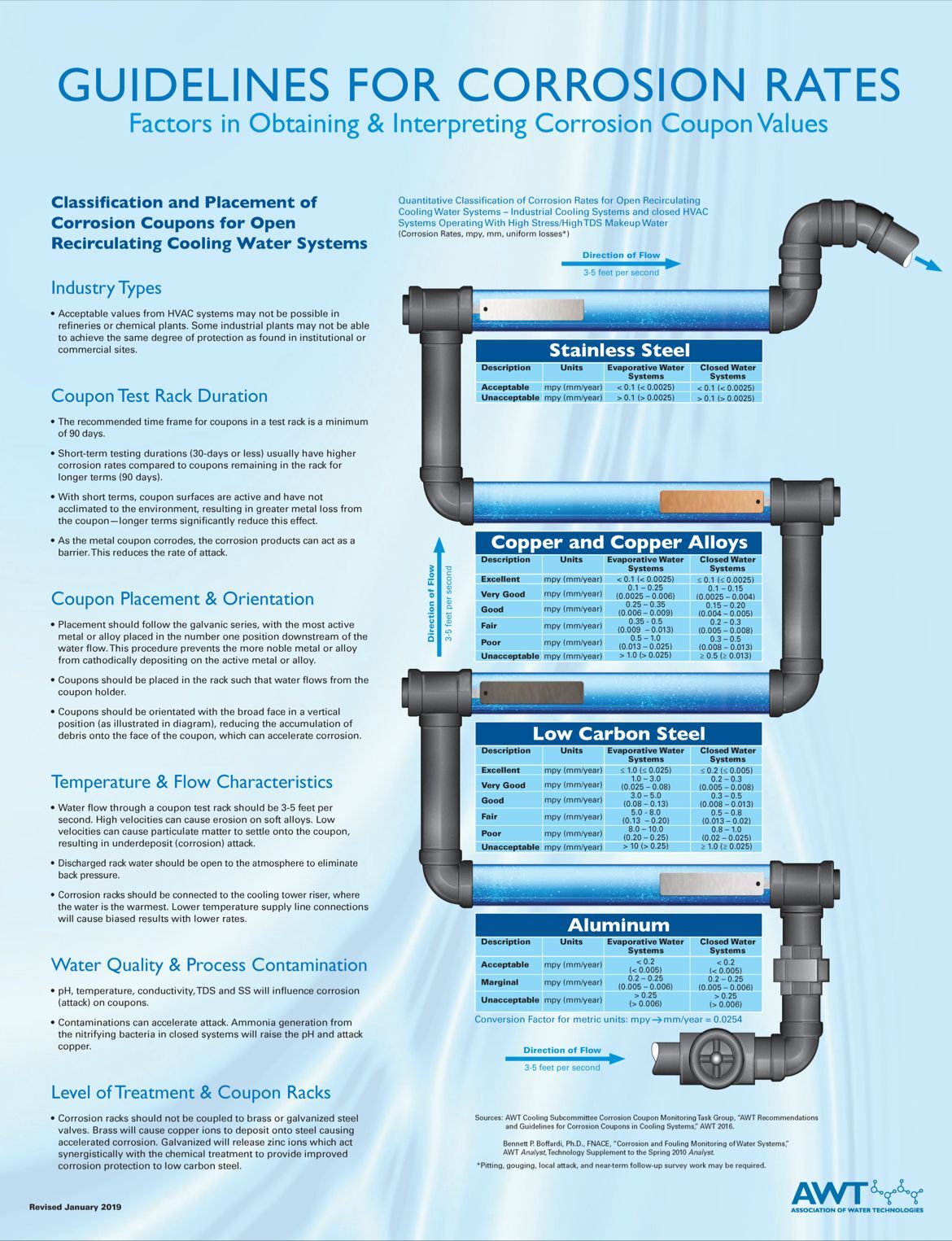

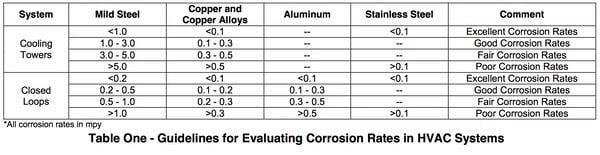

- Mild Steel: < 2 MPY (excellent control)

- Copper: < 0.2 MPY (excellent control)

- Galvanized Steel: < 1 MPY (excellent control)

Laboratories with field experience—such as Brothers Laboratory Services—can add value by helping contextualize unusual results and correlating findings with system conditions or treatment changes.

Creating a Comprehensive Corrosion Monitoring Strategy

Corrosion coupon testing provides the most meaningful insights when performed consistently and paired with supporting water quality data. Best practices include:

- Testing quarterly (four times per year) for reliable trend analysis

- Running duplicate metals for comparison, redundancy, or multi-alloy systems

- Evaluating coupon data alongside loop chemistry (pH, alkalinity, inhibitor levels, conductance, etc.)

- Tracking long-term trends to assess treatment effectiveness and operational stability

For programs that already include routine loop analyses—such as BLS BL-LOOP-BASIC or BL-LOOP-PREMIUM—adding corrosion coupon testing provides a more complete picture of system health by combining chemical data with the physical measurement of metal loss.

Built by Water Treaters

As a laboratory built by water treaters, BLS understands that corrosion testing isn’t just about producing a number, it’s about interpreting that number in context.

Our corrosion coupon analysis helps you:

- Verify that your treatment program maintains acceptable corrosion rates

- Identify alloy-specific vulnerabilities (e.g., copper vs. steel)

- Support compliance documentation for audits or customer reporting

We process and analyze coupons for water treatment companies nationwide, offering reliable turnaround, photographic documentation, and detailed observations that make each report actionable.

The Role of the Laboratory in Corrosion Coupon Testing

A qualified laboratory plays a critical role in ensuring that corrosion coupon testing produces accurate, consistent, and actionable data. Key elements of a strong laboratory partner include:

- A full range of corrosion coupon materials and processing options

- Accurate corrosion rate calculations supported by photographic documentation

- Technical interpretation informed by real-world water treatment experience

- Consistent reporting formats that support long-term trending and compliance

- Support for water treaters and facility managers who rely on dependable data

Brothers Laboratory Services follows these standards to help ensure that corrosion coupon results are reliable and meaningful. Beyond measuring metal loss, we work to provide context that helps professionals understand what the data reveals about system health and treatment performance.

Take Action: Quantify Corrosion Before It Becomes Costly

Corrosion often progresses quietly until it leads to leaks, plugging, or premature equipment failure. Regular corrosion coupon testing offers a proactive way to measure system performance and verify that your water treatment program is providing adequate protection.

By establishing a routine monitoring schedule, water treatment professionals can detect changes early, adjust chemistry with confidence, and avoid the significant expenses associated with uncontrolled corrosion.

AWT Guidelines

A guide for Water Treatment Professionals from www.AWT.org