Testing the Fresh Water Entering Your System

What is Makeup Water?

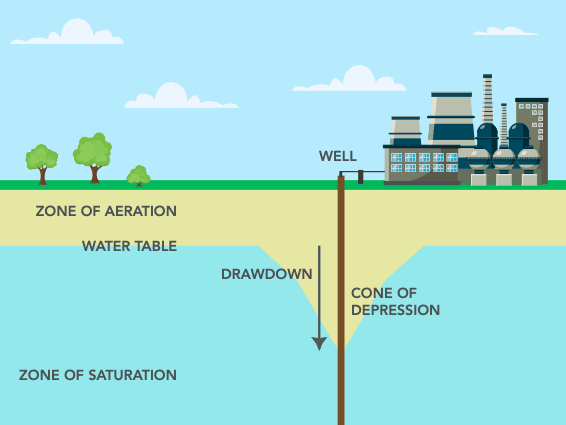

In heat transfer systems such as steam boilers, cooling towers, and closed loops, water is lost through blowdown, evaporation, or leaks. That water must be replaced with fresh supply water, commonly called “makeup water.”

Why Makeup Water Matters

The type and concentration of contaminants in makeup water directly affect the efficiency, reliability, and longevity of any treatment program. Understanding what’s in your water is the critical first step.

How We Measure Quality at the Laboratory

Field testing with portable kits can provide quick snapshots of a few parameters like pH and hardness, but they are limited in scope and precision. At Brothers Laboratory Services, we provide comprehensive analytical testing of makeup water.

Our laboratory can measure a full panel of minerals, metals, and other contaminants, delivering the objective data needed to make informed treatment and equipment decisions. We do this through the use of one code, BL-MAKEUP, to save time filling out that normally long chain of custody.

Why Testing Matters

- Identify key risks– Hardness, silica, chlorides, and other impurities can contribute to scaling, corrosion, and system inefficiencies.

- Support treatment planning– Lab data helps water treatment providers choose the right pretreatment equipment (softeners, RO, dealkalizers, etc.) and the correct chemistry.

- Predict accumulation– Now one can model how contaminants will concentrate in boilers, cooling towers, and loops over time.

- Protect investment– Data-driven adjustments to feed rates, blowdown cycles, and system controls reduce risk and lower operating costs.

Partnering With Your Water Treatment Professional

Our role at BLS is to deliver precise, unbiased results that allow water treatment experts to tailor their programs effectively. By knowing exactly what is in your makeup water, our treatment partner can apply the right strategies to prevent corrosion, scaling, fouling, and microbiological issues.